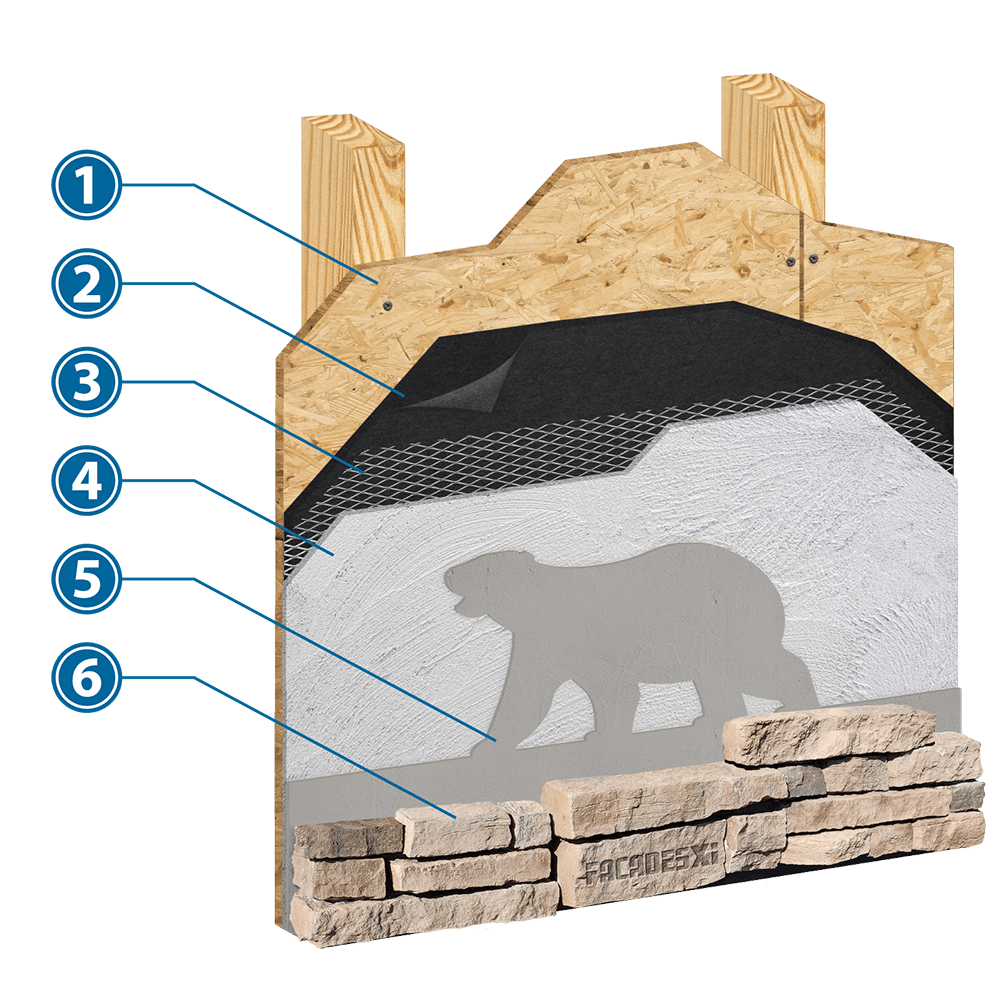

Masonry Veneer Mortar Assembly

This system is a tested and engineered wall assembly of thin veneers adhered to enhanced mortar beds with the most advanced, high strength mortar to ensure stone adhesion. FXI Masonry Veneer Systems offer the look of full sized stone, brick, with the lower weight for lower construction costs and schedules.