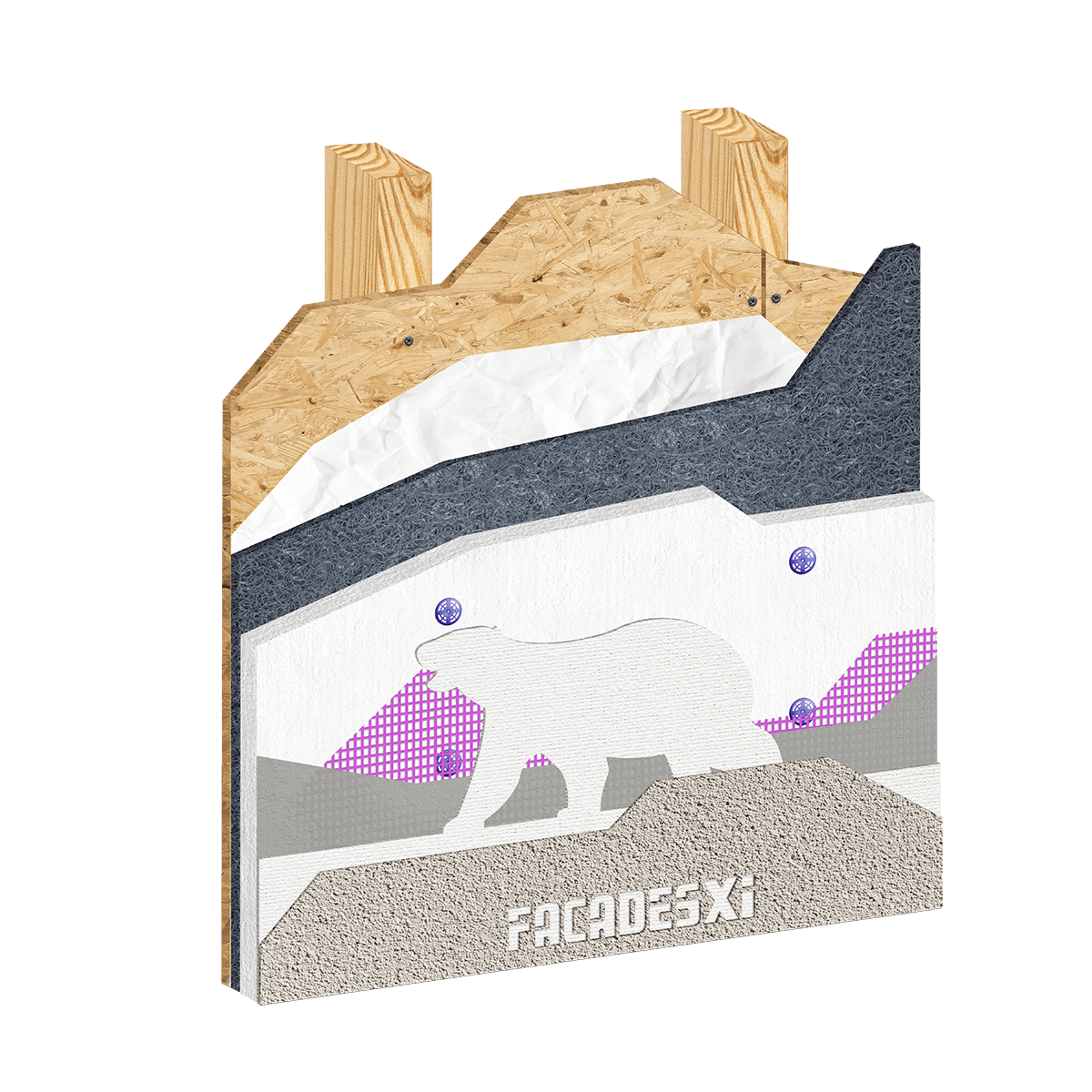

Xterior Insulation Mechanically Fastened

Xi-Fastened Systems are tested, warranted, code compliant and engineered Exterior Insulation Finish System with a code complaint water barrier and means of drainage, continuous Xterior Insulation, and countless integrally colored finishing options. Mechanical Fasteners allow the attachment of EIFS to substrates that adhesive attachment is not possible. Xterior insulation gives this system the ability to meet any energy code requirements with the ease of one system and the design flexibility and lightweight system for any designers vision.