FacadesThree Xi Series

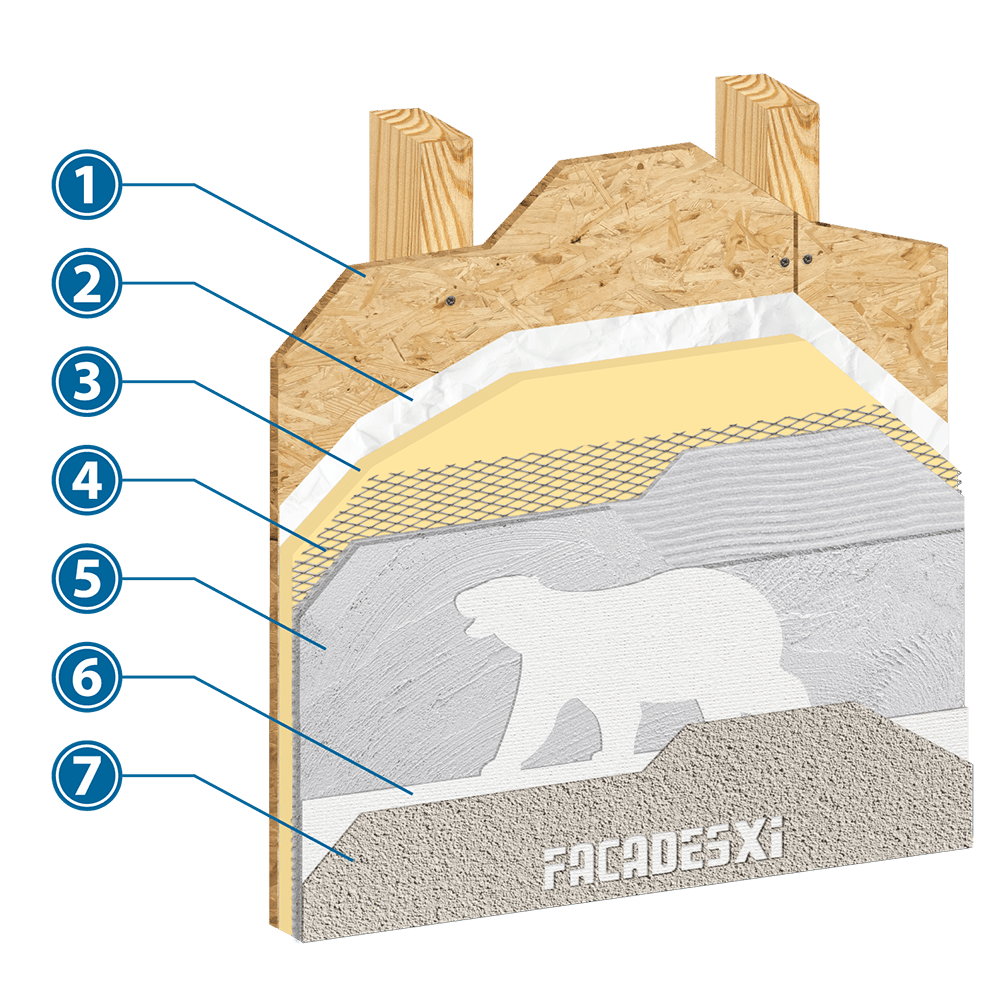

This system is a tested and engineered Three Coat stucco wall assembly with continuous Xterior Insulation. In addition to enhancing a building’s energy efficiency, Xi may help lower condensation within the building envelope.

FacadesThree Xi Series

This system is a tested and engineered Three Coat stucco wall assembly with continuous Xterior Insulation. In addition to enhancing a building’s energy efficiency, Xi may help lower condensation within the building envelope.

Exterior, interior, high impact requirement, new, retrofit, residential, multi-family, commercial, panelized, institutional, hotels, hospitals, retail centers, schools, condominiums, and government facilities

| FacadesThree Xi Series | DWG | |

|---|---|---|

| ASSEMBLY OVERVIEW – ISOMETRIC | Download | |

| ASSEMBLY OVERVIEW | Download | |

| PRODUCT SELECTION OVERVIEW | Download | |

| FOAM SHAPE | Download | |

| OUTSIDE CORNER | Download | |

| NAIL FIN WINDOW HEAD | Download | |

| NAIL FIN WINDOW SILL AND JAMB | Download | |

| STOREFRONT DOOR HEAD AND JAMB | Download | |

| EXPANSION JOINT | Download | |

| CONTROL JOINT | Download | |

| DISSIMILAR SUBSTRATE AT INSIDE CORNER | Download | |

| TERMINATION INTO DIRECT APPLIED SOFFIT | Download | |

| SYSTEM FASCIA TO DIRECT APPLIED SOFFIT | Download | |

| TRANSITION TO ADHERED VENEER | Download | |

| PIPE CONDUIT | Download | |

| VENT ATTACHMENT | Download | |

| LIGHT FIXTURE ATTACHMENT | Download | |

| FOUNDATION | Download | |

| DECK | Download | |

| PARAPET | Download |