FACADESXi Xi-WATERSHIELD

DESCRIPTION AND USAGE

Introducing the Xi-WaterShield Family of air and waterresistant barrier coatings and accessories, for use with FACADESXi Xterior EIFS, Stucco, Masonry Veneer and Cement board systems. Upgrade your system (and your warranty) to the single source WaterShield Advantage from FACADESXi.

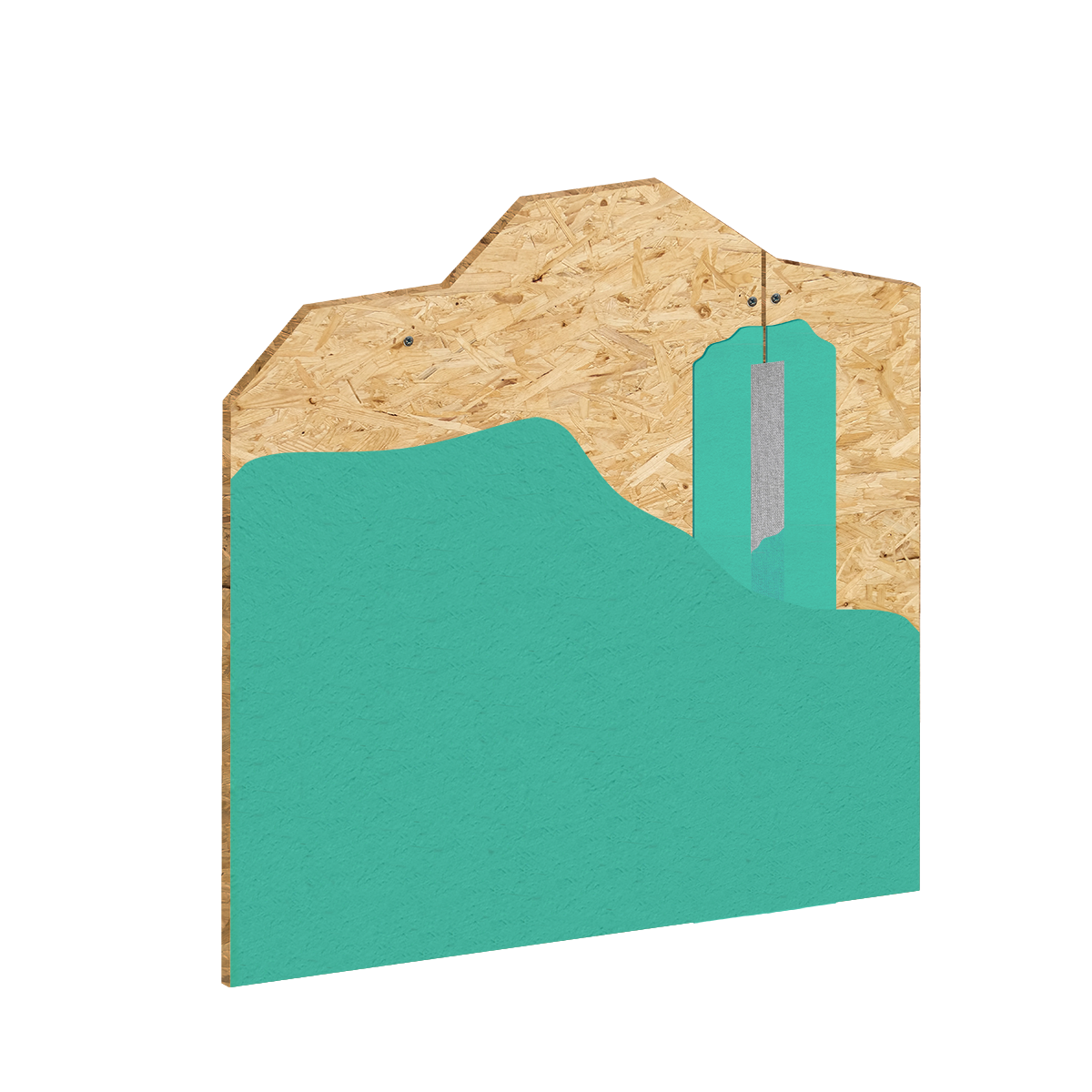

Xi-Watershield is fluid-applied by spraying or rolling under any cladding, creating a monolithic water-resistive and air barrier. Watershield is durable, will not be ripped or torn during environmental conditions and is UV Stable.

- Code compliant for use under EIFS and any cladding

- Vapor Permeable

- Low VOC

- Durable under air and wind pressures

- Easy / Fast installation

- Single product use with reinforcing fabric and joints and connections.

Water & Air Barrier Coating used in conjunction with the Xi-WaterShield Accessory Products for all FACADESXi Systems and for use under any Cladding.

Required Water & Air Barrier Coating with:

- Xi-Watershield Xterior Insulation System

- FacadesOne Xi-WaterShield System

- FacadesThree Xi-WaterShield System

- FacadesXi Elite Masonry Veneer System

Optional WaterShield Upgrade with:

- FacadesXi Stucco Systems

- Cement Board Systems

- Code compliant Claddings

- Masonry Veneer Assemblies

Allowable Substrates:

- ASTM C1177 type sheathings: DensGlass® sheathing, GlasRoc® sheathing Weather Defense® sheathing, eXP® sheathing

- ASTM C1325 Type A Exterior cement-board: PermaBase

- Poured concrete/unit masonry/brick

- Untreated Exposure I or exterior plywood sheathing (grade C-D or better)

- Untreated Exposure I OSB

- Gypsum sheathing (ASTM C79/ ASTM C1396)

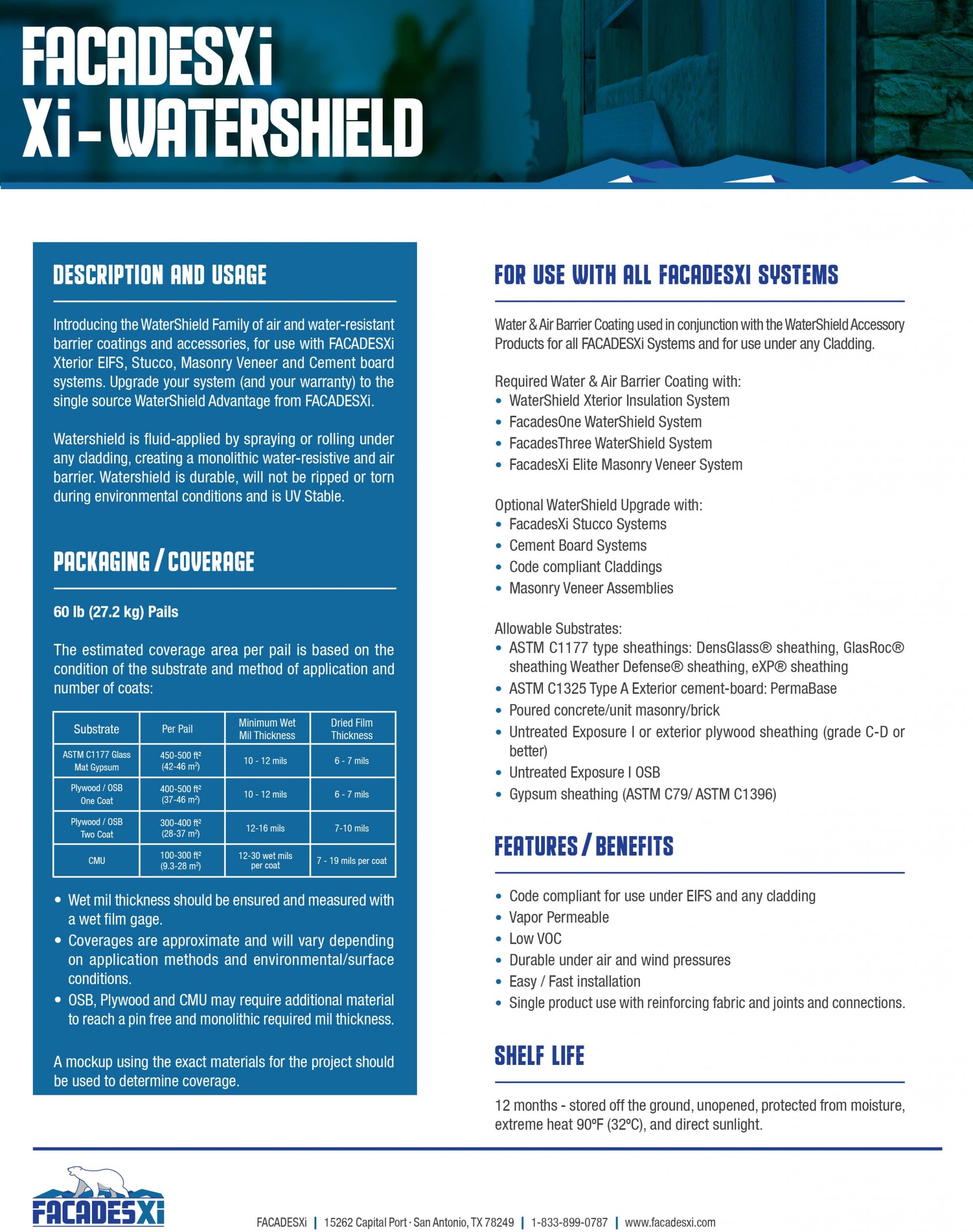

60 lb (27.2 kg) Pails

| Substrate | Per Pail | Minimum Wet Mil Thickness |

Dried Film Thickness |

|---|---|---|---|

| ASTM C1177 Glass Mat Gypsum |

450-500 ft² (42-46 m2) |

10 – 12 mils | 6 – 7 mils |

| Plywood / OSB One Coat |

400-500 ft² (37-46 m2) |

10 – 12 mils | 6 – 7 mils |

| Plywood / OSB Two Coat |

300-400 ft² (28-37 m2) |

12-16 mils | 7-10 mils |

| CMU | 100-300 ft² (9.3-28 m2) |

12-30 wet mils per coat |

7 – 19 mils per coat |

- Wet mil thickness should be ensured and measured with a wet film gage.

- Coverages are approximate and will vary depending on application methods and environmental/surface conditions.

- OSB, Plywood and CMU may require additional material to reach a pin free and monolithic required mil thickness.

A mockup using the exact materials for the project should be used to determine coverage.

Get all Documentation you Need

Get all Documentation you Need- Go To Documentation Center